The pandemic of 2020 has involved a lot of loss. As we approach Thanksgiving I know we won’t have the big family gathering that’s such a pleasure this time of year. I imagine most American families will likewise miss one or many of their close relations that they might only see on Thanksgiving. Jokes about avoided political conversation aside, this is another on the long, heartbreaking list of Losses of 2020.

So, when a close friend, whose kids are out of state, asked to join us for Thanksgiving this year, how could I say no? We’re all hurting, and maybe we can share a little bit now while we hope for more togetherness in the future. How to do this right: honoring the sacrifices we’re all making, minimizing risk and taking our joy where we can? There’s a lot in the public space about groups, and I’m not going to focus on that. In short, we’re keeping our gathering very small: Nik, myself, our son who lives a few miles away, and our friend who I see every week for dog walking.

What I’m going to describe below is managing virus transmission risk indoors. We’ll be sitting down to share a meal: the riskiest way to socialize.

As part of my work on high performance and energy efficient homes I had a chance to talk to a longtime air quality researcher and advocate. In the context of managing risk in public schools he said there are three things that are effective at reducing virus spread (keep in mind, this is in the context of low occupancy and mask wearing):

- Ventilation. This means bringing in fresh air to dilute and remove pollutants and exhaled particles. The amount of ventilation is important: to effectively reduce the potential for infection transmission minimum 40 cfm/person. This is really only realistic in buildings that have a ventilation system. For our Thanksgiving dinner, in a house without a ventilation system, we’re not going to be able do much about that. If you have a ventilation system, turn it up!

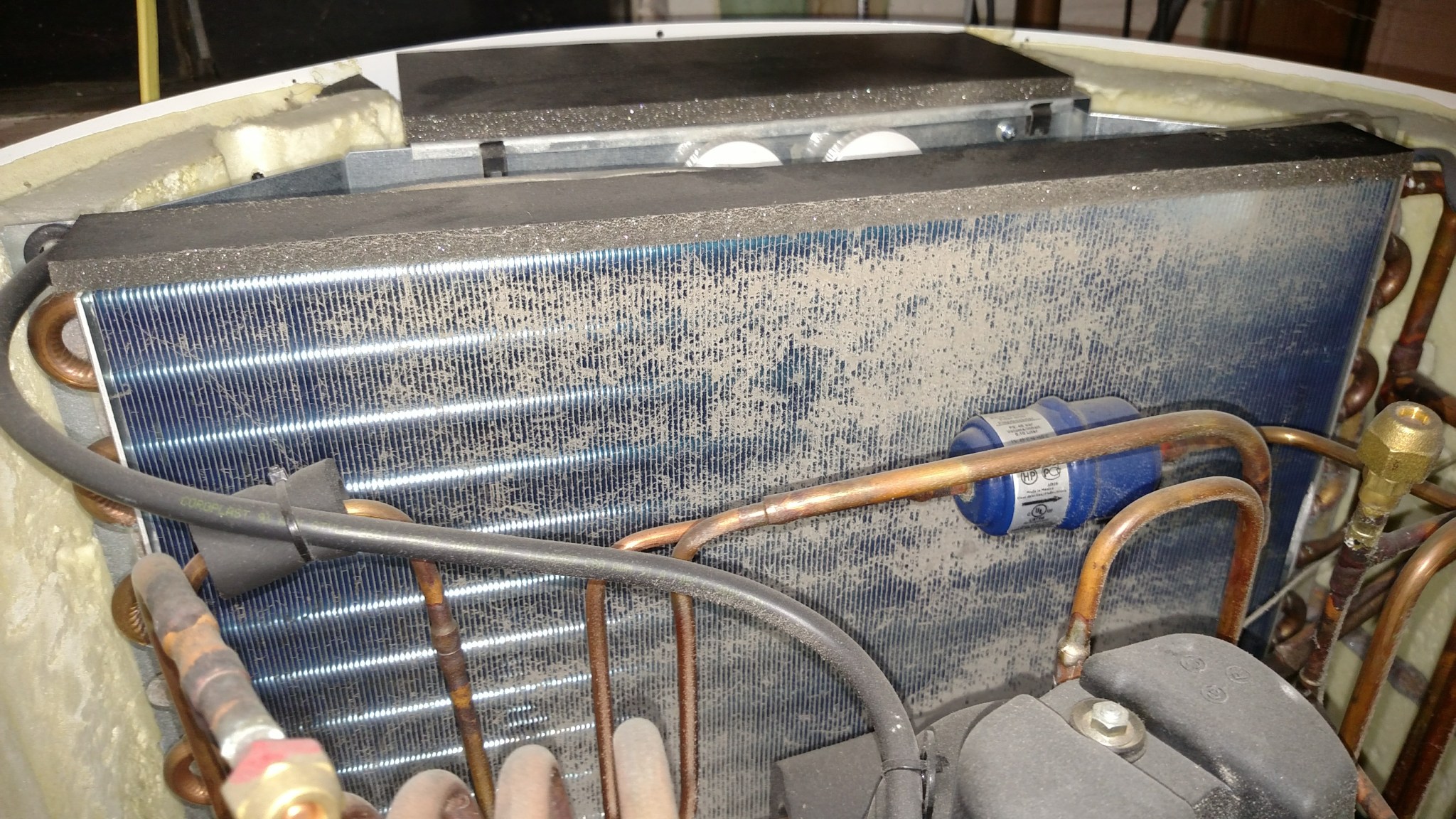

- Filtering. This one’s a bit easier, and below I explain how to do this in your house. You need to filter for particles as small as one micron. Filters are rated on the MERV scale. A MERV 13 (or higher) filter will do the job. Such filters are a little more expensive than your average filter, but they are readily accessible and available in pretty much any standard size. If you have a furnace, you can put a MERV 13 filter in there, though it might restrict air flow to the point the furnace or your comfort suffers. Buy one, try it out, watch for trouble. If all is well, bulk buy for a better price. If you don’t have a furnace, or your furnace can’t handle the MERV 13 filter, see below.

- Air disinfection. This one requires an expensive device that may be hard to procure in the middle of a pandemic. UV air cleaners come in many different varieties, from something that goes in a central HVAC system to something that sits on the floor like a dehumidifier. Some treat the whole building, others just one room. At my first dentist’s visit during the pandemic I found that they had a room-sized UV device in each examination room, mostly to protect the dental techs. Bottom line with these is, if you feel like you need one, and you can find one to purchase, they are effective. Know that they are expensive and needed for institutional settings more so than your home.

In an environment where people are indoors for an extended period of time, the combination of these three measures reduces the likelihood of infection to 30% of what it would otherwise be (remember, this assumes low occupancy and mask wearing). No it’s not zero. If you need zero, stay home and get your groceries delivered.

So, here’s what we’re going to do for Thanksgiving:

- If it’s warm, we’ll dine outside. Indoors everyone wears a mask.

- Open a window downstairs and one upstairs. Maybe two. Depends on the weather. Windy weather will help. If you live in a mild climate, or have the type of fan that goes in a window, you can help get enough air flow by actively moving air through the open window. Yes, we’ll lose heat and burn more fuel doing this: so be it.

- Two homemade air filters.

That’s it.

Homemade air filter parts:

- 20” box fan (the kind that sits on the floor. I saw two at the local second hand store! I also have a round fan that came with the new house. I’ll cobble something together to make that work.

- Five 20”X20”X1” MERV 13 furnace filters. I bought a case of 12 online for about $100.

- Wide masking- or packing tape (2” minimum)

With the airflow arrows pointing into the center of the box, assemble a box of the five filters, taping the sides for a seal. Lap the corners so the open end of the box is the same size on all four sides. Tape the box to the INFLOW side of the fan, again using enough tape to seal. Make sure to leave the electrical cord on the outside. Arrange the contraption so it can draw air into all five filters (put it on a chair, etc). On low speed, pull air out of the room, into the filters and blow it into another room. We’ll have one of these on either side of the dining room, blowing down the hall.

The absolute ideal scenario is having these contraptions near the ceiling, and allowing return air flow near the floor. Realistically, I’ll probably put these at knee-level and the return air will just make its way around the fan: under and over.

Finally, there continues to be indications that coronavirus decays more rapidly with higher relative humidity, and stays viable longer with lower relative humidity. From a building science point of view, this is bad for buildings in cold climates. But now is the time to unambiguously choose human health over building durability and energy efficiency. I don’t have a humidifier, but if I can get my hands on one between now and Thanksgiving I may add that into the freakshow of pandemic devices cluttering the dining room floor.

Find joy. Stay safe. With kindness, Li Ling and Nik